Introduction to Concrete Foaming Brokers: Making It Possible For the Surge of Lightweight, Energy-saving Concrete Equipment

Concrete frothing agents have actually become a transformative component in contemporary building and construction, making it possible for the manufacturing of lightweight oxygenated concrete with improved thermal insulation, reduced architectural tons, and enhanced workability. These specialized surfactants create secure air bubbles within the concrete matrix, causing materials that integrate strength with reduced thickness. As urbanization increases and sustainability comes to be a core top priority in structure style, frothed concrete is gaining grip across residential, commercial, and infrastructure tasks for its versatility and ecological benefits.

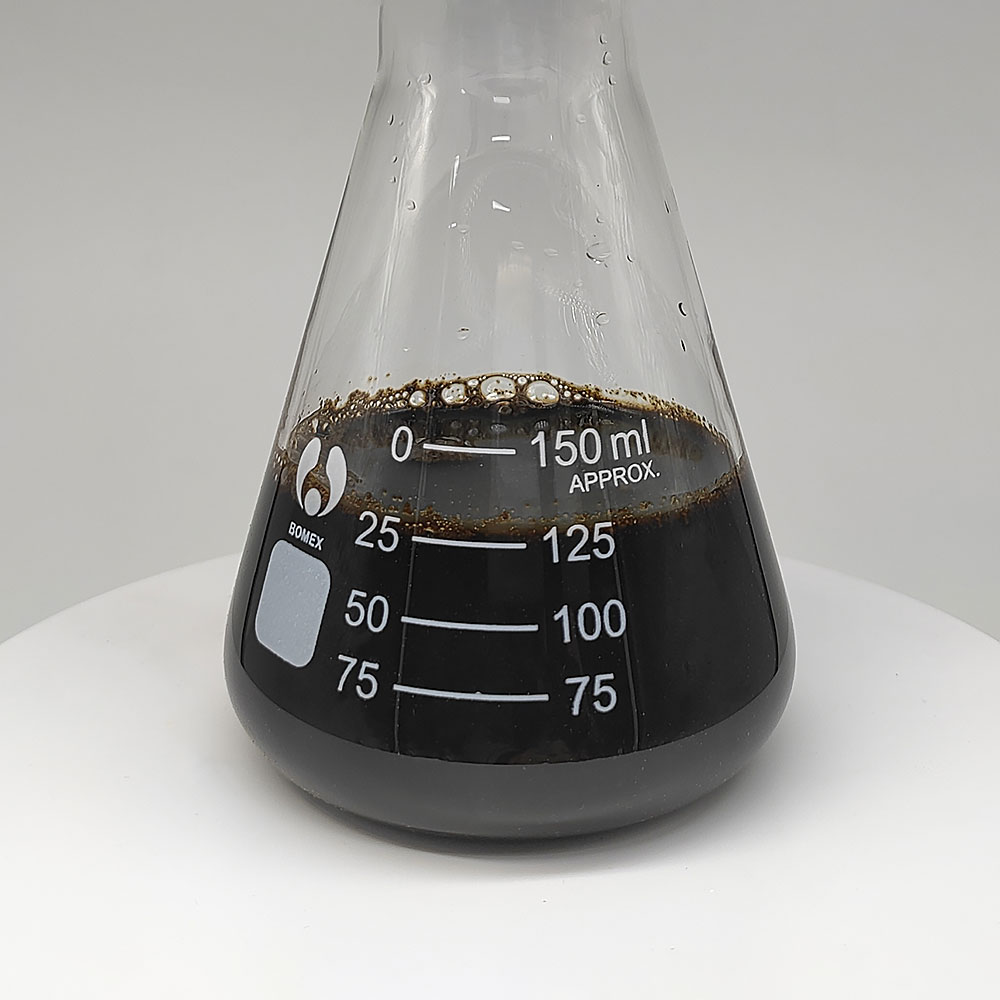

(Concrete foaming agent)

Chemical Structure and Mechanism of Activity

Concrete foaming representatives are commonly based upon protein hydrolysates, artificial surfactants, or hybrid solutions made to support air bubbles throughout mixing and healing. When introduced into the concrete slurry, these representatives reduce surface area stress and facilitate the development of attire, fine-cell foam structures. The stability of the foam is essential– poorly stabilized bubbles can coalesce or collapse, bring about irregular thickness and jeopardized mechanical properties. Advanced frothing representatives now include nano-additives and rheology modifiers to enhance bubble retention, flowability, and early-age strength growth in foamed concrete systems.

Production Refine and Foam Security Considerations

The production of foamed concrete entails two main methods: pre-foaming and blended frothing. In pre-foaming, air is produced independently making use of a foaming maker before being combined into the cementitious blend. Combined frothing introduces the foaming representative directly into the mixer, producing bubbles sitting. Both techniques require precise control over foam generation, dose rates, and blending time to guarantee optimum efficiency. Elements such as water-to-cement proportion, ambient temperature level, and concrete sensitivity substantially affect foam security, motivating recurring study right into flexible frothing systems that maintain consistency under differing problems.

Mechanical and Thermal Qualities of Foamed Concrete

Frothed concrete exhibits a distinct mix of mechanical and thermal features that make it optimal for applications where weight decrease and insulation are essential. Its compressive stamina ranges from 0.5 MPa to over 10 MPa depending on density (normally between 300 kg/m six and 1600 kg/m three). The visibility of entrapped air cells significantly enhances thermal insulation, with thermal conductivity values as reduced as 0.08 W/m · K, rivaling standard insulating materials like increased polystyrene. Furthermore, lathered concrete offers fire resistance, acoustic damping, and wetness regulation, making it ideal for both structural and non-structural components in energy-efficient structures.

Applications Across Residential, Commercial, and Framework Sectors

Foamed concrete has actually found widespread usage in floor screeds, roof insulation, space filling, and premade panels as a result of its self-leveling nature and ease of positioning. In domestic building, it works as an effective thermal obstacle in walls and foundations, adding to easy power savings. Business designers utilize foamed concrete for elevated access floors and protected dividers. Facilities applications include trench backfilling, railway trackbeds, and bridge joints, where its low weight reduces planet pressure and negotiation dangers. With growing focus on green building qualifications, frothed concrete is progressively deemed a lasting choice to standard dense concrete.

Environmental Benefits and Life Process Assessment

Among the most engaging advantages of foamed concrete hinge on its reduced carbon impact contrasted to typical concrete. Reduced material consumption, reduced transport expenses as a result of lighter weight, and improved insulation efficiency all contribute to reduce lifecycle emissions. Many frothing representatives are stemmed from eco-friendly or biodegradable resources, further sustaining environmentally friendly building practices. Researches have shown that replacing basic concrete with lathered choices in non-load-bearing applications can cut symbolized carbon by approximately 40%. As regulative structures tighten around exhausts and resource performance, frothed concrete stands out as a key enabler of lasting city development.

Challenges and Limitations in Practical Deployment

( Concrete foaming agent)

In spite of its lots of benefits, lathered concrete faces numerous challenges that limit its fostering in traditional building and construction. Problems such as drying out contraction, delayed establishing times, and level of sensitivity to inappropriate blending can endanger performance otherwise thoroughly managed. Surface ending up may additionally be a lot more complicated due to the permeable framework, needing specialized finishes or garnishes. From a supply chain viewpoint, schedule and price of high-performance frothing representatives stay obstacles in some regions. Moreover, lasting toughness under extreme climatic problems is still being evaluated through area tests and increased aging tests. Resolving these restrictions calls for proceeded development in solution chemistry and building and construction methodology.

Advancements and Future Instructions in Foaming Representative Development

Study is proactively advancing toward next-generation frothing agents that supply remarkable efficiency, wider compatibility, and improved environmental credentials. Advancements consist of bio-based surfactants, enzyme-modified healthy proteins, and nanotechnology-enhanced foams that improve mechanical stamina without sacrificing insulation residential or commercial properties. Smart frothing systems with the ability of adapting to real-time mixing problems are being discovered, together with combination right into digital building and construction systems for automated application and quality assurance. As additive production push on in construction, foamed concrete formulas suitable with 3D printing are also emerging, opening brand-new frontiers for architectural imagination and useful layout.

Provider

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Concrete foaming agent, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: concrete foaming agent,concrete foaming agent price,foaming agent for concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us